CRTS:Solvent Drying Towers

This page contains general information relating to the use and running of the Solvent Drying Towers, operated by the CRT.

Live Updates

Please find more specific, latest information here.

Solvent Availability

There are currently 10 solvent lines running on the Solvent Drying Rigs in Chemistry, with 3 down temporarily due to lack of replacement parts. 3 more are not in common use as there is not sufficient demand for them.

These are:

| Level 6, C1 | 307, RCS1 | ||

|---|---|---|---|

| Left Hand Rig | Right Hand Rig | Left Hand Rig | Right Hand Rig |

| Hexane | Diethyl Ether | Methanol | DCM (Methylene Chloride) |

| Acetonitrile | Toluene | Toluene | Diethyl Ether |

| Ethanol | THF (Tetrahydrofuran) | DMF (Dimethylformamide) | Hexane |

| DMF (Dimethylformamide) | DCM (Methylene Chloride) | DCM (Methylene Chloride) | THF (Tetrahydrofuran) |

If you would like to register your interest in having more/other solvents made available on the Drying Rigs then please contact Bill Mason as demand is being continuously assessed.

Solvent Quality

The purpose of operating Solvent Drying Towers is to provide dry solvents for water sensitive chemical reactions. This is a key area where Solvent Drying Towers are not only safe than solvent stills, but can also produce solvent which is orders of magnitude drier than ever possible in a still.

Solvent dryness is expressed as ppm of water in the solvent. Recommended results for all of the solvents are:

However, the Solvent Drying Towers can typically produce far drier solvents with a small amount of experience on the part of the supervising technician.

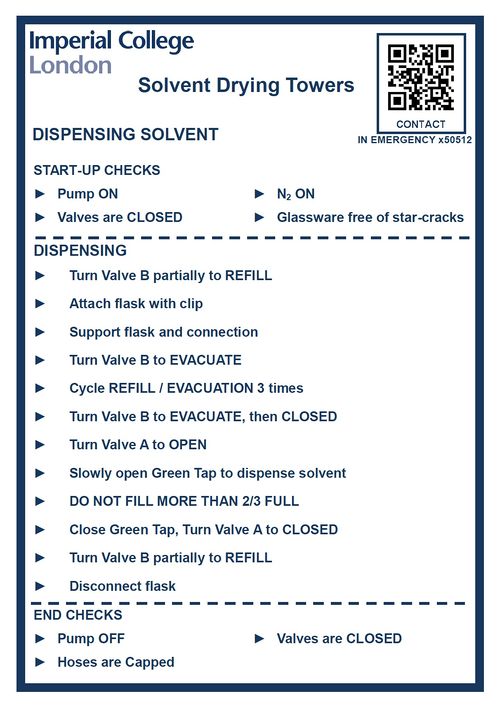

Solvent Dispensing Instructions

These instructions are intended to serve as a reminder for authorised users and a source of information for first time users. They do not constitute sufficient training for users to operate the solvent drying rig without having attended the compulsory training course and being registered as authorised users.

Standard Dispensing Instructions

Here are the standard dispensing instructions as found on the solvent towers.

Emergency Procedures

A full and thorough risk assessment has been carried out, which is available, and goes into more detail about the hazards associated with the Solvent Drying Towers. The immediate response required in emergencies is detailed here - separated into Chemical, Fire and Gas.

Chemical

In the event of a chemical spill - mop up small spills (<10mL) with blue roll; anything larger and you should evacuate the area to a safe distance and call for technical support.

In the event of a spill occurring where you are not able to prevent the release - use the emergency N2 shutoff valve on the left of the rig. If possible, you can also shut-off the solvent feed from the reservoir canister.

Cutting the N2 feed should stop the solvent from dispensing (it is forced through the columns by N2 gas pressure). The system is operated at a slight positive pressure so this may not be immediate, but should be fast nevertheless. Cutting off the solvent feed from the reservoir canister seals this off and should also prevent more solvent from leaking.

Fire

In the event of a fire - sound the fire alarm and evacuate to safety.

If you are able to you can use the N2 shutoff valve on the left hand side of the rig. Operating this valve should remove all N2 feed to the rig and prevent any more solvent from being dispensed.

If you are unable to reach this valve you can also shut off the N2 feed from the cylinder.

If you are able to tackle the fire use a CO2 extinguisher as a first choice. Sand would also be an appropriate solution in the event that a static pool of solvent is on fire.

This training should have been provided as part of basic lab safety training as operated by the Department.

Gas

In the event of a large release of gas you will hear the release and should evacuate immediately. Call for technical support and prevent anyone else from entering.

In the event of extraction failure a flow-rate monitor should sound and the Magnehelic should show an 'unsafe' reading. Evacuate, call for technical support and prevent anyone else from entering.

Safety

Basic Safety

The Solvent Drying Towers were introduced as an alternative to solvent drying stills as inherently safer, not to mention they can dry solvent to a much greater degree and at a lower cost.

As there is no heating required the main introduction of fire risk is effectively eliminated. There are still concerns over build up of static as solvent moves through the system, however being metallic the towers have the advantage that they can be (and are) grounded. Users will also ground themselves upon first touching the system to make use of it, so there are very few possibilities of the solvent igniting.

Principles of Operation

For those of you interested in finding out how the Solvent Towers work (which I find helps develop an understanding of how to use them properly). The essential information can be found here.